Note: Some modifications shown in this post

may effect the manufacturer warranty.

Getting to work with the Black Diamond Factor.

It’s always fun getting new gear in the fall and spring, and there’s always a ritual of getting familiar with it in front of the TV with a beer and some munchies. With some products, it’s just trying it on and working the zippers, but with others, like ski boots, it often takes more to get them to fit how you want them. There are many modifications to boots you can do to get them performing to your liking, like switching out tongues and liners, and playing with different combinations of power-straps, spoilers and footbeds. As a skier that spends 99.9% of the time in the backcountry, the following is what I’ve done to my Black Diamond Factors to get them spot on for everyday use and fitting like a glove for this upcoming season.

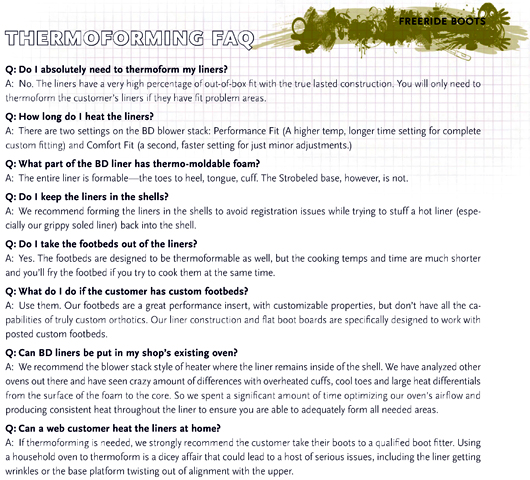

The process of fitting my ski boots began at the shop by molding some Zaps footbeds in the microwave. The footbeds that come with the Factors are thermo-moldable themselves, but we had some freebie Zaps lying around, so I opted for the additional support of an after market footbed instead. After trimming the footbeds to fit inside the liner, it was time to take the next step and actually put my foot into the boot. In a day when nearly all the top BC boots on the wall come with thermo-moldable liners, it is interesting that although the BD liners are also thermo-moldable, BD seems to be down down playing this fact and urging people to maybe by-pass this step since the liners are designed to fit a wide range of foot shapes out of the box.

Shaved off boot-board.

Once I put my feet in the liners and shells, I could feel that one foot, my right, was good and snug…but not too tight. However, the left foot felt pretty squished over the instep. The heel pocket is very pronounced in the BD boots, so I buckled the boots and walked around the house a little to allow for my heel to settle in a bit before I made any adjustments. After about 20 minutes, I still felt some uncomfortable pressure over my left instep, but instead of molding the liners, I pulled out the boot-board and shaved some material off the bottom below where it felt snug. I shaved material off the bottom, so I could leave the heat reflective material (which from my experience is not removable/reuseable) on the top of the boot-board. I started by only shaving off about a millimeter in the center of the board and then putting my foot back into the boot to see how it felt. After going back and forth a few times, focusing on where it felt snug, I eventually got the fit I was looking for. Snug…but not uncomfortably tight…while at the same time, forgoing the thermo-molding process. Here are some common questions about the Black Diamond liners.

For the entire Black Diamond Boot Tech Manual, click here.

Once I had the fit right, it was time to modify the boots more for mostly backcountry skiing use. First, I removed the rear spoiler and powerstrap. Both very nice features of the Factor. The rear spoiler is adjustable up and down on the shell of the boot (as opposed to being attached to a liner) and the power strap is wider than most, as well as having some grippy material on the back to keep it from moving around on the boot shell. However, I felt that since the Factor is way more boot than what I’ve skied in the past few years, I could go without them in favor of some weight savings. And I feel like powerstraps just tend to get in the way when you are buckling and unbuckling your boots all the time when ski touring.

Before and after grinding material off

to achieve more rearward travel in the cuff.

There is no doubt the BD boots have a really nice walk mode. The overlap construction allows for great freedom of movement than most tongue-style boots…especially when the boots are buckled. But I tend to be one of those backcountry skiers that takes long strides when touring (meaning my foot gets pretty close the tip of my opposite ski) and I thought the Factors could have a little more rearward movement in the cuff for this purpose. After examining the mechanics of the boots, I noticed that if I ground down some of the plastic on the shell, I could probably eek out a bit more travel. Tentatively, I removed the forward lean/ski-walk mechanism and started grinding.

First, I ground off some of one side of the plastic black piece, which is part of the ski/walk mechanism. The next step, was to grind off some of the plastic on the bottom of the back of the cuff…which looked to stop the cuff from moving backward more. Though I was nervous while I was doing this, since it would for sure negate any type of warranty, I felt like I was on the right track. After buffing out what I had ground off, I measured a gain of about 5/8” of rearward travel in the cuff…a noticeable increase.

The increase in rearward travel.

Anyway, that’s what I’ve done to make the Black Diamond Factors fit me like a glove and make them a little more user friendly for lots of backcountry touring. All I’m waiting for now are the AT soles so I can rock them with Dynafit bindings. And since all my skis are mounted with Dynafit, it’s a long and stressful wait. Ciao for now!

Steve – When is BD to have the Dynafit soles available? Will they be selling those as accessories that the genreal public can pick up? I’d love to try and Frankenstein those to a trail shoe for a hybrid system (was that out loud?)….cause who knows when the Pierre Gignoux carbon boot will find me

not sure i understand. these aren’t dynafit compatible.. can you seriously change out the sole?

Wick…not sure when they will available…hopefully soon. They will be available to the public. I think for $40.

Hart

The parts of the sole that fit in the ski binding are detatchable and can be swaped from the standard alpine binding compatible ones that the factors come with to a dynafit compatible set.

http://www.bdel.com/pdf/F08_TechManual-Boots-sm.pdf

there are pictures on pge 7 of this tech manual pdf.

Any issues with shaving the bottom of the boot board? It appears the bottom is designed to fit like a puzzle to prevent movement. I have heard the recommended approach is to peel off the felt and remove material from the top. Playing with one of the boot boards, however, peeling off the felt does not appear to be something that is designed to happen. Any clarification would be great. Thanks.

Steve,

Are you thinking you are going to do a lot or all of your touring on these? They seem awfully heavy for that. What about your Green Machines? Has your tune changed on those?

Cowdog,

I don’t see any issues with the boot board moving around. The heel section is nearly intact…so that holds it in place. Also, it fits snuggly around the whole outside next to the shell…so it can;t really go anywhere. I found removing the heat reflector material challenging.

Ty,

I don’t think I will use the Factors on all my tours. I think the weight would be harder to accept on longer tours. I do see myself using them for Wimpys, Albright, Middle Teton etc.. Bigger tours…like the Grand and multi-day trip in the Winds…I will most likely use my Zzeros….which I think have a better weight to stiffness ratio for that type of touring.

Very nice mod to the walk mode Steve – at least that will make it a bit more tourable

Thanks Lee. The Factors have a really nice walk mode…especially when the buckles are locked down. Way different feeling than with most tongue-style boots. Having a strong rando race background, I probably take longer strides that the majority of backcountry skiers.

I thought about that modification to the boots to increase their touring range of motion as well. I’d be afraid your mod will significantly weaken the cuff. I wonder how important that area of plastic is as far as retaining the stiffness of the cuff, and I wonder what would happen if you removed that little remaining bit. You’d think the BD guys would have noticed in development that the cuff didn’t go backwards much, and if the fix was as easy as doing what you did, why didn’t the just make the mold that way?

I think it is hard to assume what the BD guys have going on their minds. And if the Method and Factor are part of their Power Series…I would expect the Efficiency Series boots to have more range of motion…if that line is still in the picture. With such a nice walk mode already, I can imagine any Efficiency Series boots to be the cream of the crop.

Honestly, I’m more concerned about the soles failing than the cuff mod. I don’t see the mod effecting the overall strength of the cuff, but I can see where snow might be able to creep up and into the ski/walk mechanism…effecting it’s performance. But I’ve had this happen to a lot of boots…without any cuff mods.

Just got my AT soles today…so i will start touring in the Factors soon.

So I finally received my AT soles and have been out touring 4 days on the Factors so far and have walked about 2 miles on dry trails. Straight up about 2000′ at the Village and also on Table Mountain. So far, no seen problem with the cuff and ski/walk mechanism after the modification. I also broke trail boot-packing through deep snow and the ski/walk mode still worked great and didn’t get plugged with snow.

Hey man where did you get your AT soles? Have been looking everywhere. BD says a minimum of 2 weeks, and none of the stores around here have them. My new factors are just sitting here itching to go.

Directly from BD!

So whats your take on these now that you’ve got a few days on them? Is the weight worth it? Quite a step up in performance from you Zeros?

The Factors are skiing, hiking and touring great. I haven’t seen any problems with the mod either. I almost feel as if the walk mode negates the extra weight. Work great in my Dynafit bindings. No problems with the BOA. I feel a significant step up in performance from Zzeros…which I will still be using for longer tours.

Steve, Nice mod. Really concerned about cutting down the back of the upper cuff there. How has it heald up for you. I am 511, 210 and am hard on gear, breaking lots of stuff.

Have you seen any wear or breakage on that mod you did? I am about to goto town on my factors and get this walk feature going with a little more ROM.

THnaks

I have not had any problems with the mod and the boots tour great. The Kitty has even mentioned seeing the boots go through the full range of motion when skinning…even uphill. I think if something was going to break on the Factors…this mod probably wouldn’t have anything to do with it.

any ideas if the range of motion issue would lead to the small toe box feeling many people report?

I notice in my methods that my toe pain goes away in an aggressive stance.

I don’t think so. I would say more range of motion would make you slam your toes into the front of the boot more when you are striding. My guess is people who are experiencing toe pain probably should be in a half size larger boot than they are now.

i guess i should have explained more. i wrote a long post that was accidentally deleted and just posted that sort one instead.

heres my thinking. if range of motion is limited so that the cuff will not go fully perpendicular to the ground (as is the case with my methods), then when one tries to stand upright or is making longer strides especially in level terrain, this will force the foot forward and the toes to the front of the boot because of the additional pressure on the calf. you’re right that a larger size would probably alleviate this…

i tried on the size 1/2 larger (a larger shell) and got some buckling in the shell…which i didn’t like.

Steve — have you adjusted the forward lean on your Factors? I have Methods, and I am having a little trouble increasing forward lean. I took off the Walk/Ski lever, and I can see where the plastic piece (the one in the photo below the backs of your boots) can now be lined up with the + mark. But when it’s lined up, the metal piece with the lever no longer seats easily. And even if it did — I don’t see how moving the plastic piece actually affects the forward lean?!

mb…I have adjusted the forward lean and it works fine. You have to move more than the just the plastic piece…also the metal piece with the ski/walk lever on it.

Remove all the screws and pieces first. Re-insert the black piece (lower for more forward lean), you may have to fiddle with the mechanism in the boot a little to get it to sit right. Then, line up the ski/walk level and tighten the screws.

Thanks Steve. It definitely took some fiddling with the mechanism in the boot, but we did get it. Then I stripped one of the threads :-). Black diamond is kindly shipping me some new parts.

Just wondering whether the Factors would be a good choice for a large advancing intermediate (6’5″, 200 lbs.). Would I be better suited to go with the Methods?

Mirken…the Methods are softer, lighter, and the cuff is a bit lower than the Factors. So if you don’t think you need something as beefy as the Factor…than the method would be a good choice. The both fit the same, so stiffness and weight are the things that set them apart from each other. I’d probably go with the Factors…since you could grow into them as your skill advance.

Steve, I saw this post and have BD factors, and I would like to try your mod to increase stride. A year later, any problems with the way the boot skis, after the mod?

Also, no pictures are showing?

Thanks a lot

rod…some of my old picture links are broken right now since an upgrade. working on the fix…but will send you a photo.

i haven’t had any problems with my factors in any way they still tour great.